Last Updated on December 14, 2023 by Wahid

Super glue, known worldwide, is renowned for its rapid bonding capabilities on various materials. Many of us are familiar with its feats on plastic, wood, or even ceramics, but does super glue work on metal? Can it be used to bind metallic objects?

Yes, Super glue works on metals. The thing is, it depends on the material you’re binding since super glue is limited to metals. Due to this, super glue can be replaced with alternatives that are stronger and more effective. For example, polyurethane glue and epoxy glue are better than super glue because of their higher sticking strength. Moreover, considering the vast array of metals and their unique properties, the significance of using the right type of glue becomes even more pronounced.

In this exploration, we’ll show you how to use super glue on metal surfaces, how to bond them, and how to make informed decisions as you proceed. In order to truly understand adhesives, we have to understand their science, including cyanoacrylate, the main component of super glue.

Best Glues For Metal You Can Buy

1. Gorilla Epoxy: Best epoxy metal glue

2. UniBond No More Nails Original: Best heavy-duty glue for metal

3. Loctite Super Glue Precision: Best super glue for metal

4. Bob Smith Clear Slow-Cure Epoxy: Best fast-drying glue for metal

5. Aleene’s 94830 Jewelry & Metal Glue

6. Art Institute Glitter Designer Dries Clear Adhesive Bundle

What Is Super Glue?

No products found.

Super glue, known to chemists as cyanoacrylate, is a powerful adhesive that bonds quickly and securely. Its name “super” isn’t just a marketing ploy but a testament to its exceptional bonding abilities. But what exactly is this ubiquitous adhesive?

- At its core, cyanoacrylate is the main chemical compound that gives super glue its remarkable adhesive properties. It’s a fast-acting resin that can bond materials together within seconds, achieving a strong and durable bond with minimal application.

- When cyanoacrylate comes into contact with moisture, even the minute amounts present in the air or on most surfaces, it undergoes a chemical process called polymerization. This rapid transformation from liquid to solid state is what makes super glue set so quickly.

- Historically, the discovery of super glue was somewhat serendipitous. During World War II, Dr. Harry Coover and his team were researching materials to make clear plastic gun sights.

- Although cyanoacrylate wasn’t suitable for that particular purpose, its powerful adhesive properties were immediately recognized. It wasn’t until 1958, however, that this “accidental” invention was commercialized, and it quickly became a household name.

- Today, super glue’s common uses extend far beyond just household repairs. From medical applications, where it’s used as a tissue adhesive in surgeries, to automotive industries, hobbyist crafts, and even in forensic labs for fingerprinting, the versatility of super glue is truly impressive.

However, its ability to bond a wide range of materials, including plastics, ceramics, and yes, metals, has solidified its position as one of the world’s most relied-upon adhesives.

Does Super Glue Work On Metal?

Absolutely, super glue does work on metal. However, like all adhesive applications, the effectiveness hinges on the specific conditions and requirements of the bond. Let’s explore this further.

- When you question, “does super glue work on metal?”, you’re essentially delving into the realm of adhesive science.

- Cyanoacrylate, the primary component of super glue, exhibits a rapid bonding property when it comes into contact with moisture.

- Given that metals, like most materials, have trace amounts of moisture on their surface, super glue can bond them effectively.

- The strength of this bond is remarkable, often surpassing the tensile strength of many materials.

- However, it’s essential to remember that while super glue provides a robust initial bond, its long-term durability on metal can be influenced by factors like the metal’s type, surface condition, and the environmental stresses it might undergo.

- For instance, while super glue might form an excellent bond between two aluminum sheets, the same bond might not fare as well under continuous tension or exposure to fluctuating temperatures.

- Another aspect to consider is the surface smoothness. Metals with a rougher or textured surface can often provide a better grip for the adhesive, enhancing the bond’s strength.

- Conversely, very smooth or polished metal surfaces might require a bit of surface preparation, such as roughening with sandpaper, to achieve an optimal bond.

In summary, while super glue is certainly capable of bonding metal surfaces together, understanding the nuances associated with different metals and conditions can ensure that the bond is not just strong but also durable and long-lasting.

Common Myths About Super Glue & Metal

Super glue has been a go-to adhesive for various applications for years, and as with many popular products, myths and misconceptions abound. When it comes to the query, “does super glue work on metal?”, separating fact from fiction is crucial. Let’s debunk some common myths related to super glue and its efficacy on metal:

Myth 1: Super glue bonds instantly and permanently on all metals.

Fact: While super glue does bond quickly, the strength and permanence of the bond can vary depending on the type of metal and its surface condition. Metals with oxidation layers or coatings might pose challenges for an instant bond.

Myth 2: Super glue can replace welding or soldering for metals.

Fact: Super glue is an effective adhesive for many metal-to-metal applications. However, it cannot match the strength and durability of welding or soldering, especially for load-bearing or structural purposes.

Myth 3: All super glues are the same for metal applications.

Fact: Different super glues have varying compositions and properties. Some are formulated specifically for metals, while others might be more suitable for plastics or porous materials.

Myth 4: Super glue protects metals from rusting.

Fact: Super glue itself does not provide rust-proofing capabilities. If rust prevention is a concern, the metal needs to be treated or coated before bonding with super glue.

Myth 5: Super glue ruins metal surfaces.

Fact: If applied correctly and in the right amounts, super glue should not damage metal surfaces. However, removing it improperly or using excessive amounts can lead to residue or discoloration.

Myth 6: Painted or coated metals bond just as well with super glue as bare metals.

Fact: While super glue can bond to painted or coated metals, the adhesive is technically bonding to the paint or coating. Surface preparation, such as sanding or cleaning, can help ensure a more effective bond.

Myth 7: Super glue is impervious to environmental factors when used on metals.

Fact: Prolonged exposure to UV rays, extreme temperatures, or moisture might affect the bond’s strength and longevity, even when the adhesive is used on metal surfaces.

Myth 8: Metals bonded with super glue can withstand high temperatures.

Fact: Most standard super glues can handle minor temperature fluctuations but may weaken under extreme heat. For high-temperature applications, specialized high-temperature-resistant adhesives are recommended.

Understanding these myths and the truths behind them can make all the difference when deciding on the best adhesive strategy for metal. Remember, while super glue is indeed versatile, ensuring you’re using it appropriately and for the right applications is key to achieving the best results.

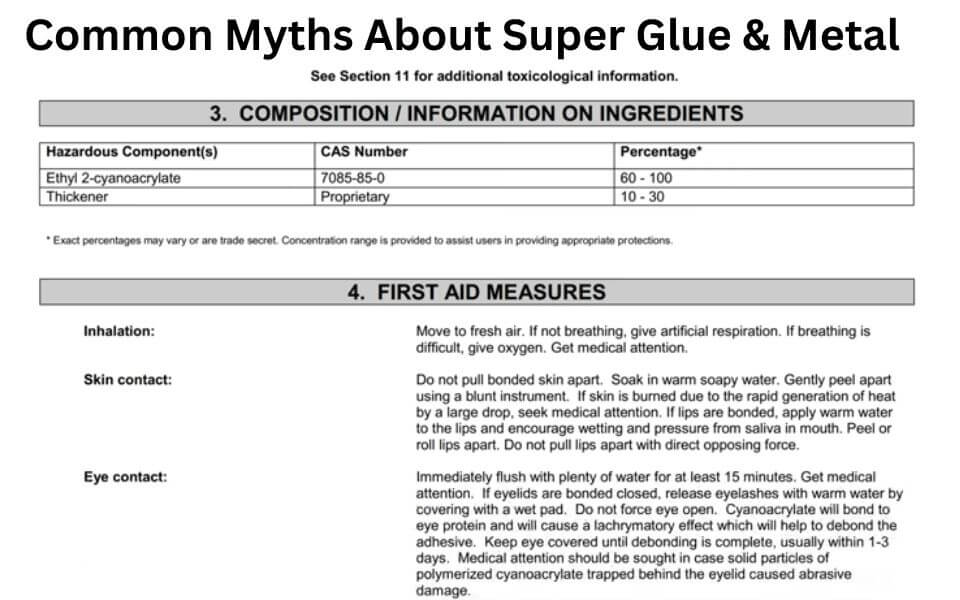

Safety Precautions When Using Super Glue on Metal

When addressing the topic, “Does super glue work on metal?”, it’s not just about the effectiveness of the adhesive but also about ensuring safety during its application. Super glue, with its rapid bonding properties, demands caution to prevent unintended bonds or potential harm. Here are some crucial safety reminders:

- Skin Contact: Super glue is infamous for its ability to bond skin instantly. Always handle it with care to avoid accidental spills or contact. If the glue does get on your skin, refrain from forcibly pulling it apart. Instead, use acetone-based nail polish remover or warm soapy water to gently loosen the bond.

- Eye Protection: When working with super glue, especially in close quarters or during extended periods, wear safety goggles. If the glue splashes and contacts the eyes, it can cause severe irritation. In such instances, rinse with plenty of water and seek medical attention immediately.

- Ventilation: While the fumes from super glue aren’t overly toxic, they can be irritating to some individuals. Ensure adequate ventilation in the workspace to dissipate any vapors, especially when working with large quantities.

- Storage: Store super glue in a cool, dry place away from children and pets. Given its rapid bonding properties, it’s essential to prevent any unintended access. Ensure the cap is securely tightened post-use to avoid any accidental spillage.

- Flammability: Some super glues can be flammable. It’s crucial to be aware of this, especially if working near open flames or high-temperature environments.

- Disposable Gloves: Consider wearing disposable gloves when working with super glue. This can prevent skin contact and also keep fingerprints off the metal surface, ensuring a cleaner bond.

- First Aid: Always have a first aid kit nearby when working with adhesives. In the off chance of any accidents or reactions, immediate remedial actions can be taken.

- Reading Instructions: Different super glue brands and variants might come with specific instructions or precautions. Always read the label and manufacturer’s guidelines to ensure safe and effective application.

In conclusion, while the utility of super glue on metal is undeniable, safety should always be the top priority. By being vigilant and adhering to these precautions, one can ensure not only a successful bonding process but also a safe and hazard-free experience.

Factors Influencing The Effectiveness Of Super Glue On Metal

While we’ve touched upon some primary aspects that affect the performance of super glue on metal, several more intricate factors come into play, emphasizing the complexity of adhesive science. Let’s further delve into the factors that can influence how super glue interacts with metal:

- Surface Texture: Smooth surfaces might not offer an optimal grip for the adhesive. Sometimes, slightly roughening the metal surface with fine sandpaper can create micro-abrasions, allowing the super glue to anchor better and form a more robust bond.

- Metal Porosity: Certain metals or metal alloys can be more porous than others. The tiny pores can trap air, which might affect the adhesive’s curing process or the strength of the bond. Ensuring the surface is as non-porous as possible, or choosing an appropriate glue variant, is essential.

- Application Technique: How the glue is applied can be a game-changer. Applying too much can result in a weaker bond, while too little might not cover the desired area sufficiently. Ensuring even application without air bubbles is crucial.

- Age of the Glue: The potency of super glue can diminish over time. Using an old or expired glue can lead to reduced bonding strength. Always check the expiration date and ensure the glue has been stored correctly.

- Chemical Interactions: Certain metals might have coatings or residues that can chemically react with the cyanoacrylate in super glue, affecting its bonding capability. It’s essential to know the metal’s composition and any treatments it might have undergone.

- Physical Stresses: Super glue creates a rigid bond, but certain metals might flex or expand under specific conditions. Constant physical stress or repeated flexing can weaken or break the bond over time.

- UV Exposure: While super glue is resilient to many environmental factors, prolonged exposure to ultraviolet (UV) light can degrade the bond. If the bonded metal is to be placed in direct sunlight, one might need to consider UV-resistant super glue variants.

- Post-Application Treatment: Sometimes, the bond might be exposed to solvents or chemicals post-application, which can weaken or dissolve the super glue. Being aware of any post-application treatments or exposures is crucial.

In essence, the interaction of super glue with metal is not just a mere application but a culmination of multiple factors that determine the bond’s efficacy. Ensuring an awareness of these factors and considering them during the bonding process can lead to the most reliable and long-lasting results.

Expert Tips For Applying Super Glue On Metal

The versatility of super glue is unparalleled, making it a staple in many toolkits. However, when tackling the question, does super glue work on metal? The key often lies not just in the adhesive’s inherent properties but also in the application techniques. Let’s explore some expert tips to maximize the effectiveness of super glue on metal:

Preparation:

- Clean Surface: Before any adhesive application, it’s essential to ensure that the metal surface is clean and free from any contaminants. Use isopropyl alcohol or a suitable solvent to remove grease, dust, or oxidation layers. This ensures that the super glue has direct contact with the metal, leading to a stronger bond.

- Roughen the Surface: If the metal surface is too smooth or polished, consider lightly sanding it with fine-grit sandpaper. This creates micro-abrasions, which can increase the surface area for the glue to adhere to and enhance the bond’s strength.

- Ensure Dryness: While super glue reacts with the trace moisture on surfaces, it’s essential to ensure that the metal isn’t wet or overly humid, as excessive moisture can affect the curing process.

Application:

- Less is More: A common mistake is using too much glue, thinking it’ll lead to a stronger bond. In reality, a thin, even layer of super glue is often more effective. Excessive glue can seep out from the bonded areas, leading to messy results and potentially weakened bonds.

- Precise Application: Use a nozzle or applicator tip for precision. Ensure that the glue is applied to the areas where you want the bond to be strongest. Remember, super glue bonds rapidly, so working quickly but carefully is key.

- Press and Hold: Once the glue is applied, press the two metal pieces together and hold for at least 30 seconds to a minute. This ensures that the surfaces are in close contact, allowing the super glue to form a robust bond.

- Avoid Movement: While super glue sets quickly, it’s crucial to avoid moving the bonded pieces for a few hours, allowing the adhesive to reach its maximum strength.

- Storage: Post-application, ensure the super glue cap is tightly sealed to prevent the glue from drying out or curing inside the bottle. Store in a cool, dry place away from direct sunlight.

In summary, while the inherent properties of super glue make it apt for bonding metal, the technique and preparation play a pivotal role. By following these expert tips, one can ensure a bond that’s not just strong but also clean and durable.

10 Benefits Of Using Super Glue On Metal

Super glue, when applied to metal, offers a plethora of advantages that are not just limited to its strong bonding capabilities. Here are more benefits of using this potent adhesive on metallic surfaces:

- Temperature Resistance: Super glue can maintain its bonding strength across a range of temperatures, making it suitable for applications where the metal might be exposed to varying thermal conditions.

- Moisture Resistance: Once cured, super glue offers a decent resistance to moisture, ensuring the bond remains intact even in humid environments or occasional splashes.

- Cost-effective: Super glue is relatively affordable, especially considering its efficiency and the tiny amount required for most bonding applications.

- Ease of Application: With its fast-drying property, users don’t need clamps or to hold the bonded materials in place for long. This convenience accelerates the completion of projects.

- Minimal Residue: Unlike some adhesives, super glue doesn’t leave a bulky residue, ensuring a clean and near-invisible bond line, which is especially beneficial for aesthetic purposes.

- Gap-filling Abilities: While super glue is typically known for bonding tight-fitting parts, some variants offer gap-filling capabilities, proving useful for uneven or slightly mismatched metal surfaces.

- Non-expanding: Once applied, super glue doesn’t expand, ensuring that the bonded materials remain in their intended position without any distortion.

- Reduced Material Warping: Super glue’s quick setting reduces the time materials might be exposed to wet adhesive, decreasing chances of material warping, especially with thin metals.

- Portability: Due to its compact packaging and the tiny amounts needed for applications, super glue is easy to transport and can be a handy addition to any toolkit or craft kit.

- Broad Availability: Super glue can be found in various formulations catering to different needs, ensuring that users can find the perfect variant for their specific metal bonding requirements.

Lastly, super glue’s extensive benefits make it a versatile and reliable choice for a multitude of metal-based applications. Whether for repairs, crafts, or industrial purposes, its advantages make it a staple in adhesive selections for metal bonding.

Cons Of Using Super Glue On Metal

While super glue (cyanoacrylate adhesive) offers quick bonding and versatility, there are several cons or disadvantages to consider when using it on metal:

- Not Suitable for Large Gaps: Super glue is not a gap-filling adhesive. It works best when the bonding surfaces are close-fitting. If there are gaps or uneven surfaces, super glue might not be the best choice.

- Temperature Sensitivity: While super glue can handle everyday temperature fluctuations, it may weaken under extreme heat. It’s not ideal for applications where the metal will be exposed to high temperatures.

- Limited Flexibility: Once cured, super glue doesn’t offer much flexibility, which can be a disadvantage if the bonded metal parts are expected to flex or move.

- Difficult to Remove: If you make a mistake or want to reposition the bonded pieces, super glue can be challenging to remove without damaging the metal surface.

- Short Shelf Life: Once opened, super glue has a relatively short shelf life and can quickly become thick or set inside the bottle.

- Safety Concerns: Super glue bonds quickly to skin, and it’s easy to accidentally glue fingers together or to the metal piece. Additionally, the fumes from super glue can be irritating to the eyes and respiratory system.

- Not Always Waterproof: While some super glues are formulated to be water-resistant, not all of them are waterproof. If the bonded metal parts will be exposed to moisture or submerged in water, you’ll need to ensure the super glue used is appropriate for such conditions.

Finally, while super glue offers certain advantages in metal bonding due to its fast curing and strong bond, understanding its limitations is crucial for effective and long-lasting results. Always consider the specific needs of your project and the properties of the adhesive you’re using.

Does Gorilla Glue or Super Glue Work On Metals?

When it comes to bonding metals, both Gorilla Glue and Super Glue can be effective, but their performance is contingent upon the specific product and the application:

Gorilla Glue:

No products found.

- Original Gorilla Glue: This is a polyurethane-based glue. While it can bond metal, it’s better suited for porous surfaces like wood. Its expansive nature when drying (it foams up) might not always be ideal for metal-to-metal bonds where a tight and invisible bond line is preferable.

- Gorilla Super Glue: This is a cyanoacrylate adhesive, similar to other “super glues.” It’s designed for quick bonding and can effectively bond metal surfaces. However, like other super glues, surface preparation (cleaning, possibly light sanding) is essential for optimal results.

No products found.

Super Glue:

- Generally, when people refer to “Super Glue,” they’re talking about cyanoacrylate adhesives. These types of adhesives bond quickly and can be used on a variety of materials, including metals. However, not all super glues are created equal, and some formulations may be more effective on metals than others.

- Surface preparation is crucial when using super glue on metal. Ensuring the metal is clean and free of oils or residues will provide the best bond.

No products found.

To conclude, if you’re looking to bond metal objects, Gorilla Super Glue or a high-quality cyanoacrylate super glue would be suitable choices. Always read the product’s label and instructions to ensure it’s recommended for your specific metal and application. Remember to also consider factors like bond strength, setting time, and any other specific needs for your project.

Does Super Glue Work On Metal To Metal?

Yes, super glue, which is primarily composed of cyanoacrylate, can work on metal-to-metal bonds. However, the effectiveness and durability of the bond depend on various factors:

- Surface Preparation: The bond’s strength will be significantly improved if both metal surfaces are clean, free of oils, and slightly roughened. A light sanding and cleaning with isopropyl alcohol or acetone can help prepare the surfaces.

- Close-Fitting Surfaces: Super glue works best when the two surfaces to be joined fit closely together. It’s not a gap-filling adhesive, so if there are significant gaps or uneven surfaces between the metal pieces, the bond might not be as strong.

- Bond Area: While super glue can provide a robust bond, it’s more effective for smaller areas. If you’re trying to bond large metal surfaces, other adhesives or methods, like welding, might be more appropriate.

- Environmental Factors: Humidity can accelerate the curing of super glue, while extremely dry conditions might slow it down. Additionally, while super glue can handle everyday temperature fluctuations, it may weaken under extreme heat.

- Type of Metal: Some metals might bond better than others. For instance, metals that form oxidation layers quickly (like aluminum) might need more thorough surface preparation.

- External Stresses: Super glue can handle compressive forces well, but it’s more susceptible to shearing or peeling forces. If the bonded metal parts will be under tension or twisting stresses, it’s important to be aware of this limitation.

- Bond Durability: While super glue can form a strong initial bond, it might not be as long-lasting as other types of adhesives or methods like welding, especially in applications exposed to constant stress, moisture, or chemicals.

In summary, super glue can be effective for bonding metal to metal, especially for small-scale applications or temporary fixes. However, for more permanent or load-bearing applications, it’s essential to consider the specific requirements and possibly explore other bonding methods or adhesives.

Does Super Glue Work On Metal To Plastic?

When faced with the challenge of bonding disparate materials like metal and plastic, many wonder, “Does super glue work on metal to plastic?” Indeed, the versatility of super glue, primarily composed of cyanoacrylate, makes it a popular choice for such tasks.

Effectiveness of Super Glue on Metal to Plastic Bonds:

- Surface Preparation: Just as when bonding metal to metal, the effectiveness of the bond greatly depends on the preparation of the surfaces. Both the metal and plastic should be clean and free from oils or residues. Using isopropyl alcohol can be an effective cleaning agent for both materials.

- Type of Plastic: Not all plastics respond equally to super glue. For instance, while super glue can bond well to hard plastics, it might not adhere as effectively to certain polyethylene or polypropylene plastics without special surface treatments.

- Bond Area & Fit: Super glue excels when the bonding surfaces are close-fitting. If there are gaps, especially with plastic that can flex, the bond might be compromised.

- Environmental Factors: External factors like humidity and temperature can influence the bond’s effectiveness. While super glue typically sets faster in higher humidity, extreme temperatures can affect the bond’s durability, especially if the plastic is susceptible to warping or melting.

- Stresses & Loads: If the bonded area will be under tension, twisting, or shearing forces, it’s essential to consider super glue’s limitations. While it can handle compressive forces, plastic’s flexibility might make the bond more susceptible to shearing forces.

- Bond Durability: Super glue can create a strong bond initially, but for applications requiring long-term durability or exposure to chemicals and moisture, other specialized adhesives might be more appropriate.

In essence, while super glue is indeed a versatile adhesive capable of bonding a variety of materials, when pondering “Can super glue bond metal to plastic?”, it’s crucial to understand both the strengths and limitations of the adhesive, as well as the specific requirements of the project at hand.

How Long Does Super Glue Take To Dry On Metal?

The super glue sets and dries in 8-60 seconds on metal. To ensure a stronger bond, make sure both parts are in contact for 15-20 minutes and are left undisturbed for 24 hours for the bond to fully cure. Depending on the material’s surface, this can vary. You might have trouble drying metal surfaces if they are extra smooth.

In addition, use a degreaser when cleaning the metal surface, since it prevents dirt from sticking to the surface and speeds up drying time. Aside from that, super glue will not adhere well to wet surfaces. For polymerization and chain formation, moisture might be required, but not excessively.

Thankfully, super glue accelerators based on acetone, such as Infinity Bond and Fast Cap 2P-10 Adhesive make quick work of light metals. Alternatively, you can use baking soda to create a home-based solution. Also, super glues dry instantly and begin to set within 10 seconds or less when used with accelerators.

FAQs From Reddit & Quora On “Does Super Glue Work On Metal?”

Q1: I read somewhere that super glue isn’t suitable for all metal types. Is this true?

Answer: Yes, this is true to an extent. While super glue can bond to many metals effectively, the bond’s strength and longevity can vary depending on the type of metal and its surface conditions. Some metals with naturally occurring oxide layers might pose challenges for super glue bonding.

Q2: Does super glue resist rusting when applied to metals?

Answer: Super glue itself does not rust, but it doesn’t provide rust-proofing capabilities either. If the metal is prone to rusting, it’s essential to treat or coat the metal to prevent rust before bonding with super glue.

Q3: How does super glue compare to epoxy when used with metal?

Answer: Both super glue and epoxy offer strong bonds, but they have different properties. Super glue cures faster and is suitable for quick fixes, while epoxy typically provides a more flexible and durable bond for metals but takes longer to cure.

Q4: Can I use super glue on metal jewelry pieces?

Answer: Yes, super glue can be used on metal jewelry pieces for quick fixes, but for a more lasting bond, jewelry-specific adhesives or epoxies might be more appropriate.

Q5: Are there any LSI brands or specific super glue products that experts recommend for metals?

Answer: There are several renowned brands in the adhesive industry, such as Loctite, Gorilla Glue, and Krazy Glue, that produce super glues specifically designed for metals. However, it’s always a good practice to read product descriptions and reviews before making a choice.

Q6: Is super glue resistant to heat when applied to metals?

Answer: Most standard super glues can withstand minor temperature fluctuations but may weaken under high heat. If the bonded metal will be exposed to high temperatures, consider using a high-temperature-resistant adhesive.

Q7: Will super glue bonds on metal hold up outdoors?

Answer: While super glue can be used outdoors, prolonged exposure to UV rays, rain, and varying temperatures might affect its bond over time. It’s advisable to use an outdoor-rated adhesive for such applications.

Q8: Can super glue be removed from metal without causing damage?

Answer: Yes, super glue can often be removed from metals using acetone or nail polish remover. However, always test on an inconspicuous area first to ensure the solvent doesn’t damage the metal’s finish.

Q9: Does super glue work on painted or coated metals?

Answer: Super glue can bond to painted or coated metals, but its effectiveness might be compromised as it’s bonding to the paint or coating rather than the metal itself. Surface preparation, like sanding, can improve the bond.

Q10: What happens if I mix super glue with other adhesives while bonding metal?

Answer: Mixing super glue with other adhesives is not recommended unless specified by manufacturers. Combining different formulations can lead to unpredictable results, weakened bonds, or even harmful chemical reactions.

Q11: How Strong Is Super Glue on Metal?

Answer: A super glue’s binding strength is 4000 PSI, making it suitable for joining materials like rubber, glass, and more. Heavy metals, such as cast iron, cannot be bonded with it. Also, metal holes cannot be filled with superglue. An epoxy is a better choice for this. It also depends on the material you’re bonding the metal to that affects the strength of super glue on metal. In the case of metals and rubber, cyanoacrylates (super glues) will result in a strong bond, whereas, it is always better to use epoxies to bond metals to plastic.

Sum Up

In our exploration of the question, “does super glue work on metal?”, we’ve delved deep into the nature of super glue, its interaction with various metals, and the myriad factors that influence its effectiveness. We’ve discovered that while super glue can indeed form a robust bond on metal surfaces, its efficacy is subject to variables like the type of metal, surface preparation, environmental conditions, and more.

As we wrap up our discussion, we encourage you, our readers, to dive into the world of adhesives with an open mind. Experiment with care, always prioritize safety, and never hesitate to seek expert advice when in doubt. And most importantly, we’d love to hear from you! Share your experiences, success stories, challenges, or any further questions on super glue and metals. Together, we can continue to demystify the intricate dance between adhesives and the materials they bond.