Last Updated on December 13, 2025 by Wahid

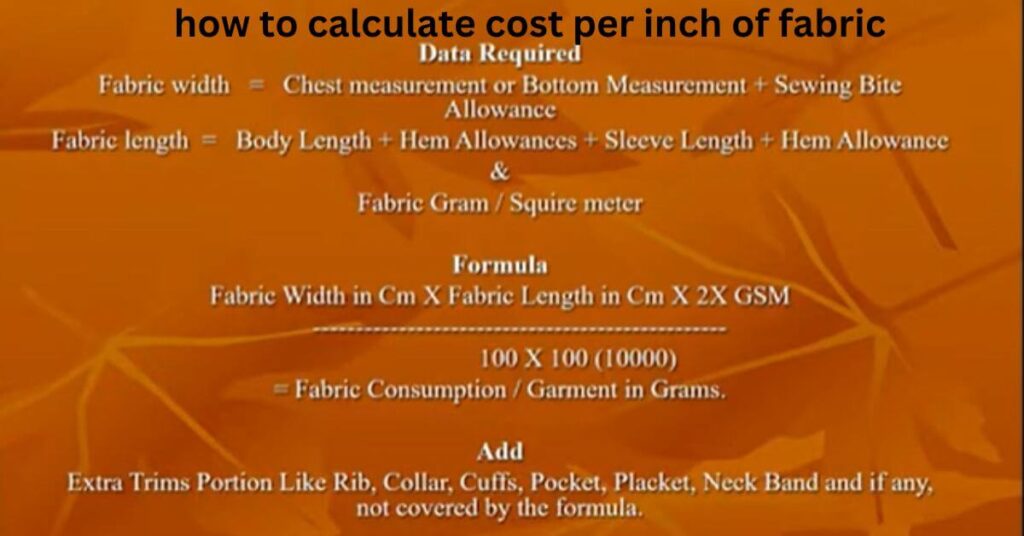

You’ve unlocked the power of cost per inch. We’re going to explore how to calculate cost per inch of fabric using a simple formula (Cost per Inch = Total Fabric Cost / Total Fabric Length in Inches), along with valuable tips for putting it into action.

Remember, mastering this skill empowers you to:

- Make informed buying decisions: No more impulse purchases – you’ll know exactly how much each inch of fabric costs.

- Compare fabric options effectively: Don’t be fooled by price tags alone. Cost per inch reveals the true value based on your actual fabric needs.

- Plan your projects with confidence: Knowing the cost per inch allows you to accurately budget for fabric and avoid project roadblocks.

The Formula: Unlocking the Cost per Inch Mystery

Now that you’ve seen the power of cost per inch, let’s unveil the formula itself. Don’t worry, it’s incredibly straightforward. Here’s the magic equation:

Cost per Inch = Total Fabric Cost / Total Fabric Length (in inches)

Let’s break this down step-by-step:

- Total Fabric Cost: This refers to the entire price you pay for the fabric, including any discounts or sales tax (we’ll discuss hidden costs later).

- Total Fabric Length (in inches): This is crucial. Most fabric is sold by the yard (36 inches), but for accurate cost per inch calculation, we need the length in inches. Don’t be fooled by yards! Always convert yards to inches for this formula.

For example, if you buy 2 yards of fabric, that’s actually 72 inches (2 yards x 36 inches/yard). Using the wrong unit (yards) would throw off your cost per inch calculation.

By dividing the total cost by the total length in inches, we arrive at the cost per inch, which tells you exactly how much you’re paying for every inch of that beautiful fabric. This simple formula empowers you to make informed decisions and avoid budget surprises!

Putting the Power of Cost per Inch to Work: Examples

Now that you’re armed with the formula, let’s see it in action with some real-world examples.

Example 1: Making Every Inch Count

Imagine you’re smitten with a stunning fabric for a new dress. You see the price tag: $25. But how much fabric do you actually need? Let’s say your pattern requires 3 yards of fabric. Here’s how to find the cost per inch:

- Convert yards to inches: We know most fabric is sold by the yard, which equals 36 inches. So, 3 yards translates to 3 yards * 36 inches/yard = 108 inches of fabric.

- Apply the formula: Cost per Inch = $25 (total cost) / 108 inches (total length) = $0.23 per inch.

Brilliant! Now you know that each inch of this fabulous fabric costs $0.23. This information is key for informed buying.

Example 2: Unveiling the True Bargain

Often, a lower overall price tag doesn’t guarantee the best deal. Let’s compare two fabric options:

- Fabric A: This beauty costs $15, but it’s only 50 inches long.

- Fabric B: This option might seem pricier at $20, but it comes in a generous 72-inch length.

Here’s how cost per inch helps us choose wisely:

- Fabric A: Cost per Inch = $15 (total cost) / 50 inches (total length) = $0.30 per inch.

- Fabric B: Cost per Inch = $20 (total cost) / 72 inches (total length) = $0.28 per inch.

Surprise! Despite the higher overall price, Fabric B is actually the more budget-friendly option at $0.28 per inch. Why? Because you’re getting more fabric for your money. This is especially crucial if your project only requires a smaller amount, like 30 inches. With Fabric B, you’d use less fabric and potentially have leftover material for another project, maximizing your value.

These examples showcase how to calculate cost per inch of fabric empowers you to compare fabric options effectively and avoid getting swayed by just the headline price. You can now make confident decisions based on the actual fabric you need and the cost per inch.

Don’t Forget These Extras: Essential Tips for Mastering Cost per Inch

While the formula is the foundation, a few additional considerations can elevate your cost-per-inch mastery:

Fabric Width: Remember, most fabric is your friend – it’s typically sold by the yard in standard widths, usually 36 or 44 inches. However, some specialty fabrics might have different widths. Don’t be caught off guard! If you’re unsure about the width, grab your trusty measuring tape and get the exact measurement before calculating the cost per inch.

Bulk Discounts: Planning a large project or simply love a particular fabric? Bulk discounts might be your new best friend! Some stores offer reduced prices per yard when you purchase larger quantities. While the total cost might seem higher initially, remember to factor this discount into your cost per inch calculation. You might be surprised to find that buying more fabric per yard actually reduces the cost per inch, especially if you plan to use every bit!

Hidden Costs: Let’s be real, the price tag on the fabric bolt might not be the whole story. Be mindful of potential hidden costs that can affect your overall cost per inch. Consider shipping fees if you’re buying online or any applicable sales tax. Factoring these extras into your cost per inch calculation ensures you have a clear picture of the true cost per inch.

However, by keeping these additional tips in mind, you’ll be a cost-per-inch pro in no time. You’ll not only be able to accurately calculate fabric needs but also identify the most budget-friendly options for your sewing projects. So, the next time you’re browsing through a fabric store, remember – a little planning and the magic of cost per inch go a long way in maximizing your fabric value!

How Do You Calculate Price Per Square Inch Of Fabric?

Here’s how to calculate the price per square inch of fabric:

Formula:

Price per Square Inch = Cost per Inch x Fabric Width (in inches)

Steps:

- Calculate Cost per Inch:

- Follow the steps mentioned earlier to determine the cost per inch of fabric (Total Fabric Cost / Total Fabric Length in Inches).

- Fabric Width:

- Remember the fabric width, which is usually 36 inches or 44 inches, but it can vary depending on the fabric type.

- Price per Square Inch:

- Multiply the cost per inch you obtained in step 1 by the fabric width in inches.

Example:

- Let’s say you buy 2 yards (72 inches) of fabric for $30.

- Cost per Inch = $30 (total cost) / 72 inches (total length) = $0.42 per inch.

- The fabric width is 44 inches.

Price per Square Inch Calculation:

- Price per Square Inch = $0.42 per inch x 44 inches (width) = $1.85 per square inch.

Therefore, in this example, each square inch of the fabric costs $1.85.

Additional Tips:

- Always pay attention to the units used when buying fabric. Fabric width is usually given in inches, but double-check the label if unsure.

- Round up your cost per inch result to two decimal places for better accuracy, especially when dealing with larger projects.

By following these steps, you can effectively calculate the price per square inch of any fabric, allowing you to make informed decisions about material usage and project budgeting.

How Do You Calculate Cost Per Unit Of Material?

Calculating the cost per unit of material is a valuable skill for any project, not just sewing! Here’s a breakdown of the formula and steps involved:

Formula:

Cost per Unit = Total Material Cost / Material Quantity (in chosen unit)

Steps:

- Identify the Unit: The first step is to figure out the unit in which your material is typically sold and used for your project. Here are some examples:

- Fabric: Yards, meters, or even fat quarters (pre-cut pieces).

- Lumber: Boards by the foot or sheets of plywood.

- Hardware: Nails by the pound, screws by the package (depending on project needs).

- Liquids: Gallons (paint), liters (oil).

- Total Material Cost: Determine the total amount you pay for the material. This includes the base price and any applicable taxes.

- Material Quantity: Find out the exact quantity you purchased based on the chosen unit.

- Fabric: You might have the number of yards or meters listed on the receipt or measured it yourself.

- Lumber: Check the receipt for the board’s length (in feet) or the plywood sheet’s dimensions (square footage).

- Hardware: The packaging will usually indicate the weight (e.g., pounds for nails) or the number of pieces included.

- Liquids: The container will display the volume (e.g., gallons for paint).

- Cost per Unit: Divide the total cost by the material quantity you obtained in step 3. This will give you the cost per unit of your chosen material.

Example:

- Let’s say you buy 5 gallons of paint for a total of $75.

Cost per Unit Calculation:

- Cost per Unit = $75 (total cost) / 5 gallons (quantity) = $15 per gallon.

Therefore, in this example, each gallon of paint costs $15.

Additional Tips:

- Pay attention to units: Double-check the units used on the label or receipt to avoid confusion. For instance, lumber might be priced per board foot, while plywood is priced per square foot.

- Bulk discounts: Consider buying in bulk if your project requires a significant amount of material, as some stores might offer discounts for larger purchases. Just ensure you have proper storage space and the material won’t expire before you use it all.

- Hidden costs: Factor in potential hidden costs like sales tax or shipping when calculating your overall material cost.

Yes, by understanding this method, you can effectively calculate the cost per unit of various materials, not just fabric. This helps you make informed decisions about material selection, project planning, and budgeting.

How Do You Calculate Material Costing?

Calculating material costing can be broken down into two main approaches depending on your specific needs:

- Cost per Unit: This method is ideal for understanding the price of a single unit of material, regardless of the project’s final size. It’s applicable to various materials like fabric, lumber, hardware, liquids, etc.

Formula:

Cost per Unit = Total Material Cost / Material Quantity (in chosen unit)

Steps:

- Identify the Unit: Determine the unit in which your material is typically sold and used for your project (yards for fabric, gallons for paint, pounds for nails, etc.).

- Total Material Cost: Find the total amount you pay for the material, including the base price and any taxes.

- Material Quantity: Measure or check the receipt for the exact quantity you purchased based on the chosen unit.

- Cost per Unit: Divide the total cost by the material quantity. This gives you the cost per unit of your material.

- Cost per Square Inch (for Fabric): This method is particularly useful for sewing projects where you need to understand the price per unit area of fabric.

Formula:

Price per Square Inch = Cost per Inch x Fabric Width (in inches)

Steps:

- Calculate Cost per Inch: Follow the steps mentioned earlier for cost per unit to find the cost per inch of fabric (Total Fabric Cost / Total Fabric Length in Inches).

- Fabric Width: Remember or measure the fabric width, which is usually 36 inches or 44 inches, but can vary depending on the fabric type.

- Price per Square Inch: Multiply the cost per inch by the fabric width in inches.

Example (Cost per Unit):

- You buy 3 yards (108 inches) of fabric for $40.

- Cost per Inch = $40 (total cost) / 108 inches (length) = $0.37 per inch.

- (Assuming the fabric width is 44 inches)

- Cost per Yard = $0.37 per inch * 44 inches (width) = $16.38 per yard.

Example (Cost per Square Inch):

- Let’s say you buy 2 yards (72 inches) of fabric for $30.

- Cost per Inch = $30 (total cost) / 72 inches (length) = $0.42 per inch.

- The fabric width is 44 inches.

- Price per Square Inch = $0.42 per inch x 44 inches (width) = $1.85 per square inch.

Additional Tips:

- Always pay attention to the units used when buying materials.

- Consider bulk discounts for larger purchases.

- Factor in hidden costs like sales tax or shipping when calculating the overall material cost.

- Round up your cost per unit/square inch results for better accuracy, especially when dealing with larger projects.

However, by mastering these methods, you can effectively calculate material costs for various projects & make informed decisions about material selection, project planning, and budgeting.

Conclusion: Sewing Smarter with Cost per Inch

So, the next time you embark on a sewing adventure, remember the magic of cost per inch. With this knowledge in your sewing kit, you can confidently navigate fabric selections, maximize value, & bring your creative visions to life, all while staying within your budget. Happy sewing!